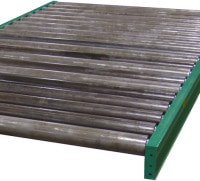

Using gravity as a power source, gravity roller conveyors are an excellent Solutions choice in many warehouse and fabrication facilities. From carton flow to loading or unloading trucks. There is almost always an application for gravity roller conveyor.

Live roller conveyors offer the automated facility the flexibility to merge product lines, accumulate product, and transport at high speeds. From line shaft to belt driven to V-belt drive; most modern facilities rely heavily upon power roller conveyors.

At Ingalls Conveyors, we manufacture, design, and re-manufacture roller conveyors. We are also a direct distributor for several major conveyor manufacturers and have the unique ability to save our customers a substantial amount of money by integrating new conveyor components with refurbished components as appropriate. Our refurbished conveyors come with an “AS NEW” warranty.

Please call 1-800-826-4554 or email info@nullingallsconveyors.com to contact one of our engineering staff members about your specific roller conveyor requirements.

Use the tabs below to browse the types of Gravity Roller Conveyors available:

- Flex Conveyor

- Skate Wheel Conveyor

- Light Duty Roller

- Medium Duty Roller

- Heavy Duty Roller

- Super Duty Roller

The ALL-STEEL construction provides unmatched structural integrity, whether the conveyor is extended, compacted or configured in simple or compound curves. Adjustable inner legs vary height to achieve gravity flow. The NESTAFLEX 226 is the choice for use in retail store level applications, packaging areas, assembly lines and in low volume shipping and receiving departments.

Standard Features and Options

Construction

All steel construction.

Conveyor formats

Available in 14″, 18″ and 24″ widths. Lengths can be tailored to your needs.

Height adjustment

Standard adjustable heights from 28″ to 44″. Other height adjustments available.

Legs

Side links

Conveyor side links are made from 11-gauge steel.

Skate wheel options

Heavy-duty casters

Axles

Skate wheel axles are 5/16″ diameter. Standard axle centers are 5 1/4″, 4″ and 3″ to handle small cartons. Other options are available.

Couplers

Couplers are standard. Optional universal connectors are available to couple to other extendable conveyor brands.

Box stop/handle

Retractable package stop serves as an ergonomic handle.

Conveyer Options

Unidirectional side guards available for special product needs.

Optional impact section available for receiving applications.

Optional swing stick available for dockless receiving applications.

Warranty

18-month factory warranty.

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

*8 skate-wheel option available on 14″ wide models |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Straight Skatewheel Track

- 45° Skatewheel Curve

- 90° Skatewheel Curve

Optional Colors available at extra cost.

Frame – Frames are 2-1/2″ X 1″ x 12 gauge powder painted formed steel or 2-1/2″ x 1″ x 1/8″ aluminum formed channels. The 12″, 15″ and 18″ wide sections have one 1/8″ x 1″ axle supports and the 24″ wide has two 1/8″ x 1″ axle supports.

Wheels – Zinc plated steel or aluminum wheels are 1-15/16″ diameter x 5/8″ face with a steel hardened raceway and a 13/16″ wide cone. Each wheel contains (7) 1/4″ hardened and ground steel balls. The lightly oiled baffled construction is designed to keep dirt out.

Cross Braces – 5 ft. long sections have (2) bolted cross members and 10 ft. long sections have (3) bolted cross members.

Axles – All axles are 1/4″ diameter cold drawn steel, set on 3″ centers and secured with a 1/4″ – 20 stop nut.

Wheel Capacity – Steel, 50 lbs; aluminum, 45 lbs.

Wheels Per Foot – Standard patterns include 8, 10, 12, 16, 18, 20, 24 and 28 wheels per foot.

Couplings – Each 5′ and 10′ section is equipped with a hook and rod connector. The slotted hook permits minor lateral movement. No tools are necessary for assembly, just hook together.

Widths – Standard widths are 12″, 15″, 18″ and 24″.

Lengths – Standard lengths are 5′ and 10′.

Curves – Standard curves are 45° and 90°. The outside radius is 4 feet. Capacity same as straight sections.

Applications / Features:

- Cartons

- Tote pans

- Assembly lines

- Shipping departments

Optional Colors available at extra cost.

Frames – 2-1⁄2″ deep x 1″ flange x 12 gauge powder painted formed steel. Rugged cross members bolted between channels.

Rollers – 1-3⁄8″ diameter x 18 gauge galvanized steel tubing with swaged ends for a firm bearing seat. Rollers have spring loaded axle for easy removal or insertion.

Axles – 1⁄4″ diameter cold rolled steel for Model 138SR; 5⁄16″ hex for Model 138SRH.

Couplings – Hook and rod.

Widths – 12″, 15″, 18″ and 24″ overall width.

Length – 5′ and 10′ long straight sections.

Aluminum, Model 138AR

Frames – 2-1⁄2″ deep x 1″ flange x 1⁄8″ heat treated aluminum. Rugged aluminum cross members bolted between channels.

Rollers – 1-3⁄8″ diameter heat treated aluminum tubing with swaged ends for a firm bearing seat. Rollers have spring loaded axle for easy removal or insertion.

Axles – 1⁄4″ diameter cold rolled steel.

Couplings – Hook and rod.

Widths – 12″, 15″, 18″ and 24″ overall width.

Length – 5′ and 10′ long straight sections.

Applications / Features:

- Cartons

- Tote pans

- Assembly lines

- Shipping departments

Optional Colors available at extra cost.

Frames – 3-1⁄2″ deep x 1-1⁄2″ flange x 10 gauge powder painted formed steel with bolt-in cross members, rollers set 1⁄4″ high. Galvanized channels optional.

Rollers – 1.9″ diameter x 16 gauge steel tubing with swaged ends to provide a firm bearing seat and rounded ends. Galvanized rollers optional. Tapered rollers in curve are 2-1⁄2″ to 1-11⁄16″ taper.

Bearings – Labyrinth sealed, lightly oiled.

Axles – 7⁄16″ hex shaft, spring-loaded.

Couplings – Butt type, for bolting sections together.

Widths – From 13″ between frames (B/F) and wider in two inch increments up to 27″; also 31″, 33″, 37″ and 39″ between rails.

Lengths – 5′ and 10′ long straight sections. Capacity – 240 pounds per roller with 1,350 pounds maximum distributed live load over 10 foot length; 3,100 pounds maximum distributed live load over 5 foot length.

Curve Degree – 45° and 90° with 2′ 8-1⁄2″inside radius for widths up to 27″ between frames. 4’0″ inside radius for 31″, 33″, 37″, and 39″ between frames.

Applications / Features:

- Cartons

- Tote pans

- Assembly lines

- Shipping departments

Optional Colors available at extra cost.

Frames – 4″ x 4 gauge steel channel with bolted cross members, powder painted. Rollers set 1⁄4″ high.

Rollers – 2-1⁄2″ x 11 gauge steel tubing with swaged bearings.

Bearings – Labyrinth sealed and grease packed.

Axles – 11⁄16″ hex shaft, spring-loaded.

Couplings – Splice plates, for bolting sections together.

Widths – 13″ between frames (B/F) and wider in two inch increments up to 27″ between frames; also 31″, 33″, 37″, 39″, 45″, 51″, 55″ and 59″ between frames.

Lengths – 10′ and 5′ straight sections.

Curve Degree – 45° and 90° with 2′ 8-1⁄2″ inside radius for widths up to 27″ between frames. 4’0″ inside radius for 31″, 33″, 37″, and 39″ between frames. Tapered roller curve available.

Capacity – 650 pounds per roller with 3,750 pounds maximum distributed live load over 10 feet for 12″ nominal roll to 3,500 pounds on widest sizes; 8,000 pounds maximum distributed live load over 5′ lengths. Curve sections same as 10′. All capacities based on 3″ centers.

Applications / Features:

- Cartons

- Tote pans

- Assembly lines

- Shipping departments

Optional Colors available at extra cost.

Frames – 6″ x 8.2 pound structural steel channel with welded cross members powder painted. Rollers set 3⁄8″ high.

Rollers – 3-1⁄2″ diameter x .30 wall with machined ends for press fit bearings.

Bearings – Labyrinth sealed and grease packed.

Axles – 1-1⁄16″ hex shaft, pinned in curved conveyor, retainer panels in straight conveyor.

Couplings – Butt type, for bolting frames together.

Widths – 7″ between frames (B/F) and wider up to 51″ between frames.

Length – 5′ and 10′ straight sections.

Capacity – 1,200 pounds per roller, with 8,400 pounds maximum distributed live load over 10 feet; 16,700 pounds maximum distributed live load over 5 feet lengths. All capacities are based on 4″ centers.

Curve Degree – 45° and 90° with 4’0″ inside radius only. Tapered rollers not available.